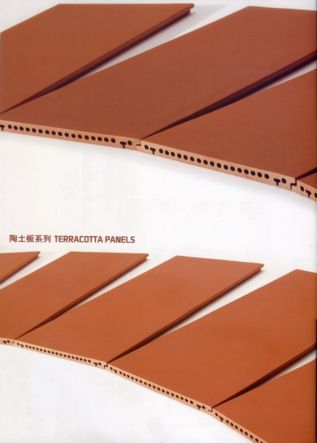

To Be the Best Curtain Wall Material

Posted By Claire on July 25, 2012

Terracotta panel as a curtain wall material, is a good choice for the architect to express the ideological concept of Humanities building. Leiyuan recommend you through six steps which is ” see, touch, listen, draw, cut, pre-trial,” to the appreciation of quality terracotta panel. To provide you with the most perfect terracotta panel product selection approach, that we never tried of.

Step One: See, color pure, panel formation

Gentle color, inimate, even without gradient can be considered as pure color. Both panel surface is without bending, warping, and can be referred to as flat. Leiyuan has a strong R&D capabilities of color, full digital control of modern production systems to achieve the same pure color in a diferent batch; and five-layers’ dry, 12 temperature-controlled aone, automatic cycle in the production line ensure the panel surface formation of a uniform minimum production of hardware.

Step Two: Touch, water frosted, feeling strong

Gently touching on the poor quality product, there will be ups and downs and thorn bump feel. Leiyuan adopted the international advanced vacuum extruder equipment, ensuring terracotta panel with uniform fine surface, such as skin-line texture arrays, combined with strong highpressure water mill process, a gentle touch will feel the natural moist.

Step Three: Scratch, sharp equipment scratch, no white spots

Friction and across on the surface of terracotta panel with the use of coins, keys or other hard objects, the scratch mark will leave on the poor quality products and can not be erased. Leiyuan terracotta panel use the microwave stable, five-layer kiln drying, and 7 hours firing, the surface is high intensity, can not easily be scratched, which greatly reduces damages in the installation and maintenance processes.

Step Four: Listen, high hardness, crisp sound

Terracotta panel are fully combined after firing a long time, uniformity density, which issued after the sound crisp percussion, shile the inferior product will have boring and no echoing sound because of uneven density. Leiyuan terracotta panel product is high hardness, strong wind pressure, sweet-sounding after knocking on the panel.

Step Five: Cut, fully quenching, same inside and outside

After cuting the terracotta panel, the inferior products will appear inconsistent color of the inside and outside of the panel, even appears black color inside the panel, this is because to save time and shorten the bruning time to reduce costs, resulting in lack of internal heat, not even been completely dried and kept the wet soil of the color. Leiyuan has the 260 meters of liln, firing more than 7 hours from the production equipment and processed, both to prevent the occurrence of such phenomena.

Step Six: Pre-Trial, tour factory, reading cases, know the quality

Inspection equipment, scale, and to visit the actal operation case will make you to see the real product strength and quality. Leiyuan Lopo has a current annual production capacity of millions square meters. Plan to build cases are all over the world. Leiyuan is curently completion projects are boutique items, have good reputation from property owners and architetures.

That’s awesome! I love this blog for the content! Thanks so much for making my life better!

Hello all, nice blog. I am happy to have founded it. I am getting a lot of useful information here. I ‘ll come back surely. Thank you to the webmaster. See you all.

Frickin’ stunning. I love it! Thanks for all you have done!